What's so great about the popular all-electric injection molding machine?

The all-electric injection molding machine is a processing injection molding machine with all power supplied by electricity. It is becoming more and more popular in the market.

The reason for its popularity is mainly because it has the performance that the full hydraulic injection molding machine cannot achieve, mainly in:

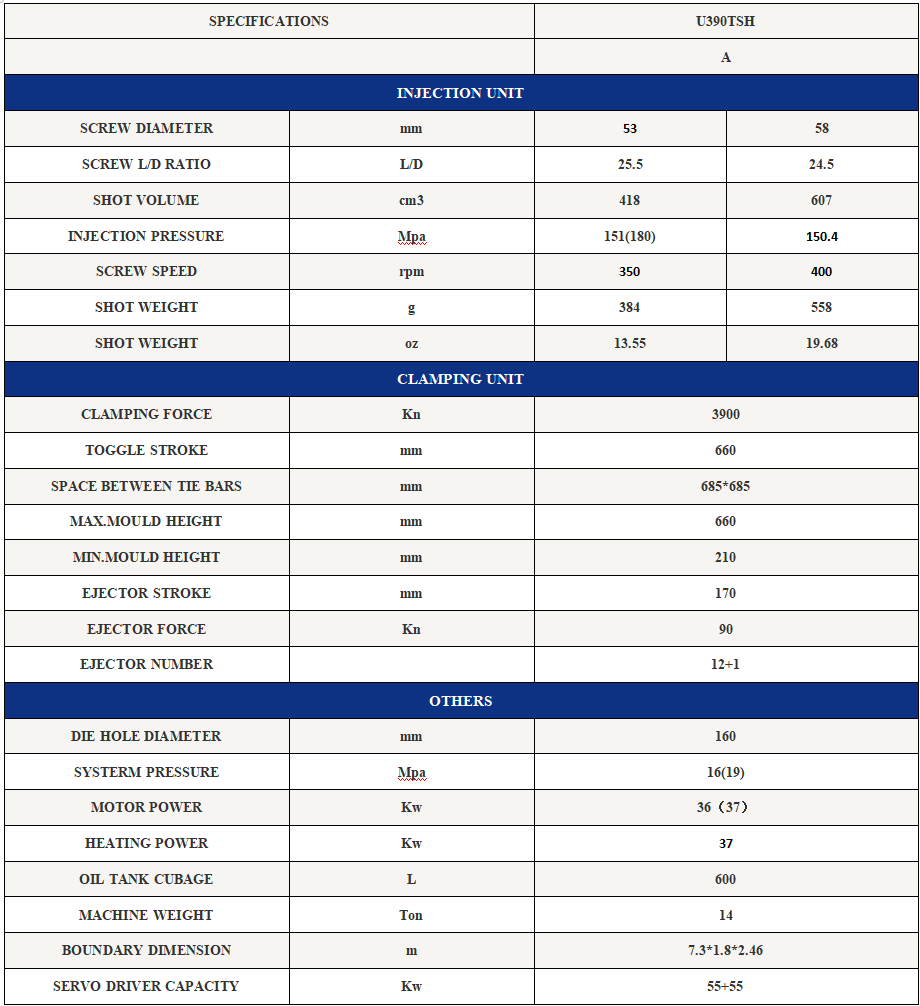

"Energy saving" is the biggest advantage of electric injection molding machines. Since the servo motor is directly driven according to the force required by each actuator, it not only improves the efficiency, but also improves the energy utilization rate, and its energy utilization rate can reach more than 95%. , so it can save 25%-60% energy than the full hydraulic injection molding machine.

The injection performance is stable. The dynamic technical parameters of the all-hydraulic injection molding machine are affected by the change of the hydraulic oil temperature and are prone to fluctuations. In contrast, the dynamic technical parameters of the all-electric injection molding machine are basically not disturbed by external factors. The molding parameters of the mold are always in line with the actual molding conditions, so the injection performance is stable, and the rapid response of the precise injection molding parameters can only be truly reflected in the servo motor system.

High efficiency, the application of servo motor improves the responsiveness of the system. Taking a series of all-electric injection molding machines as an example, its molding time is only 1/3 of that of full-hydraulic injection molding machines. Since each actuator of the electric injection molding machine is driven by an independent servo motor, it is not affected by the system. Capable of performing compound actions, for example, simultaneous ejection during mold opening and simultaneous mold closing during plasticization, thus greatly improving productivity.

Water saving, because the all-electric injection molding machine does not use hydraulic oil, only cooling water is required at the feeding port, so compared with the hydraulic injection molding machine with load-sensitive pump, the use of cooling water can be reduced by 70%, which is comparable to that of ordinary quantitative pumps. Compared with hydraulic injection molding machines, cooling water can be reduced by 90%.

Optimize the working environment, because the hydraulic oil is not used, the working environment can be kept clean, and the noise of the machine can be more than 10dB lower than that of the full hydraulic injection molding machine. While optimizing the working environment, due to the cancellation of the hydraulic system, the area of the injection molding machine can be saved by 15%.

In a word, with the advantages of high speed, high efficiency and high precision, the all-electric injection molding machine is more suitable for processing electronic, electrical, electrical, and other high value-added products, especially for the injection molding of small parts, showing its high performance, The advantages of high-precision injection molding.

Compared with fully hydraulic injection molding machines, fully electric injection molding machines have many advantages:

1. Save energy and reduce production costs

Since each action of the electric injection molding machine is controlled by the corresponding servo motor, when a certain production action is performed, other control motors do not need to run, thus greatly saving power consumption.

Generally speaking, the power consumption of the all-electric injection molding machine is only 1/3-1/4 of the full-hydraulic injection molding machine. In addition, the previous all-electric injection molding machine does not use hydraulic oil, which saves the cooling step of the working oil. The use of cooling water is greatly reduced, which can greatly reduce production costs for manufacturers.

2. High responsiveness and stability of production action control

Since all actions in the production process of the all-electric injection molding machine are driven by servo motors, which have fast action speed and high precision, and do not use hydraulic oil, various process parameters will not be affected by oil temperature changes. High stability during production.

3. The low noise feature of the all-electric injection molding machine not only benefits the workers, but also reduces the investment and construction cost in the soundproof production workshop.

4. Ensure the cleanliness and safety of the working environment

Because the all-electric injection molding machine does not use working oil, there will be no environmental pollution caused by mechanical oil leakage, and the possibility of fire can be greatly reduced.